Welding terminology pdf Marlborough

WELDING TECHNICAL TERMS 1 May 14, 2008 · The author is R.T. Miller. Quote from page 301, right hand column, 2nd paragraph in "Special Welding Processes" section under Pipe Welding found in chapter 29:" The stove pipe or position method of welding pipe, consist of lining up each section, length by length, and welding each joint while the pipe remains stationary. Since the pipe is not

Welding Terminology Welding Application Container - CDA

Welding Terminology Welding Application Container - CDA. Directory of Welding Terminology. Welding Terminology. A-C D-F G-I J-M N-P Q-S T-Z. A - C. A. ACETONE: A flammable, volatile liquid used in acetylene cylinders to dissolve and stabilize acetylene under high pressure. WELDING PRESSURE: The pressure exerted during the …, Welding is very important in shipbuilding industry. In order to protect the ship structure, this process should be performed by the qualified welders and controlled efficiently by the quality.

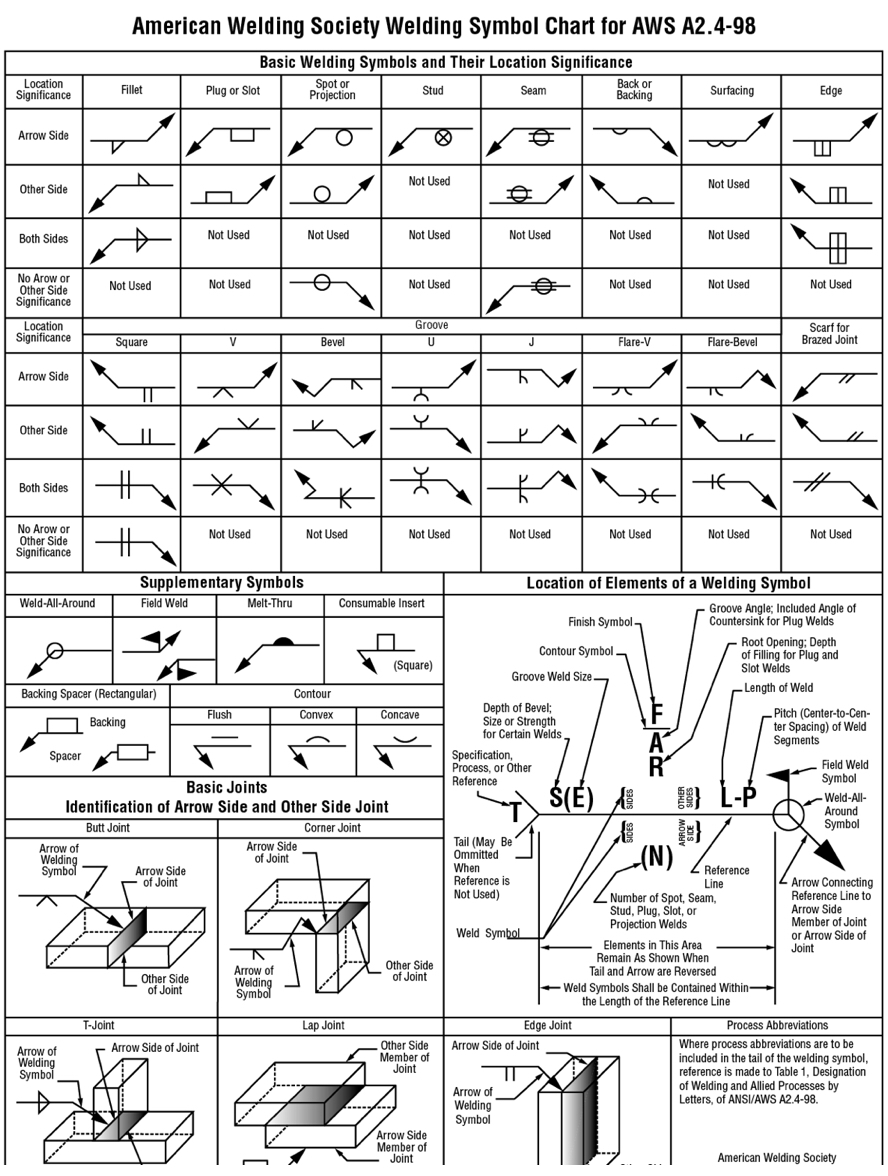

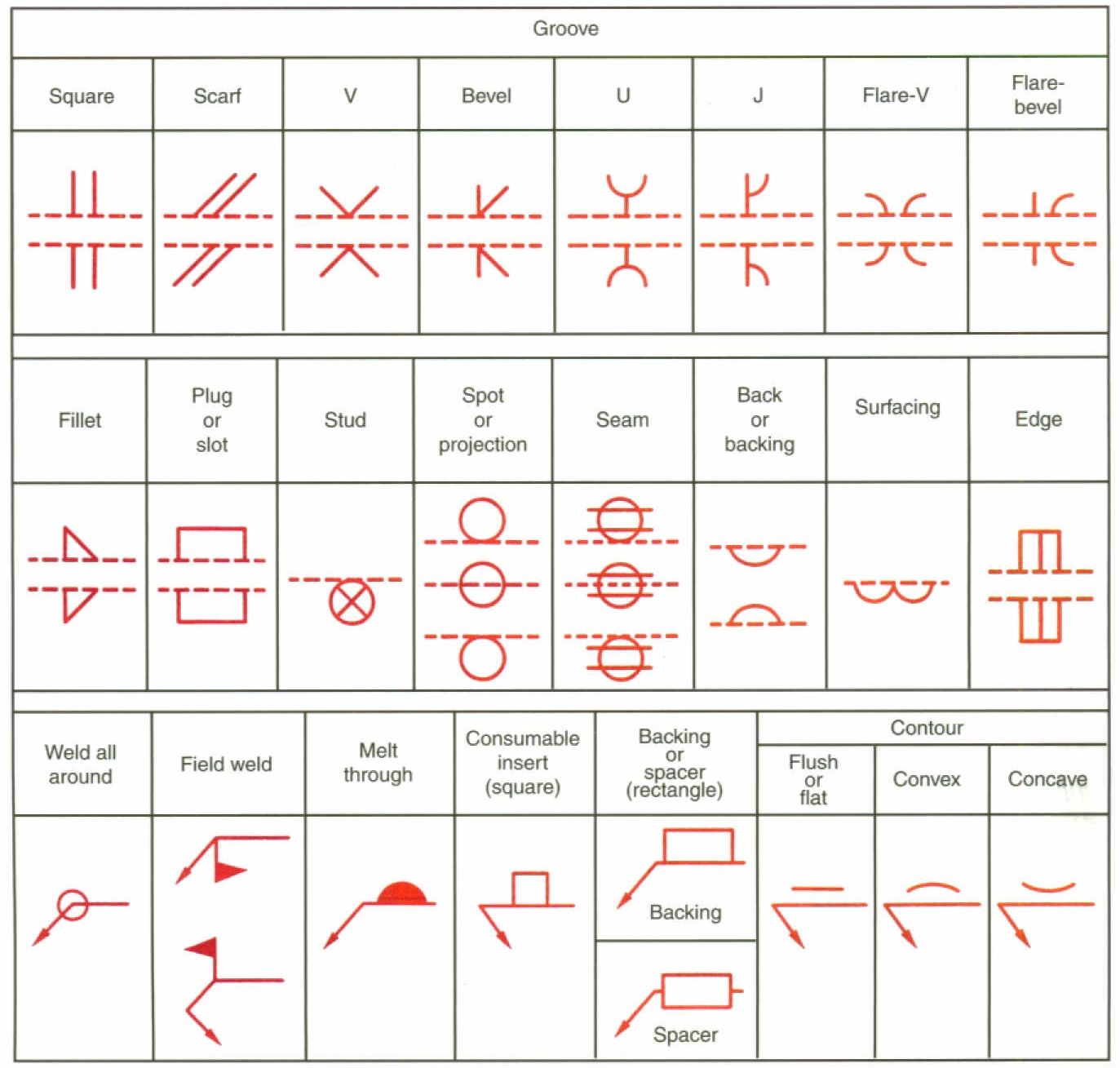

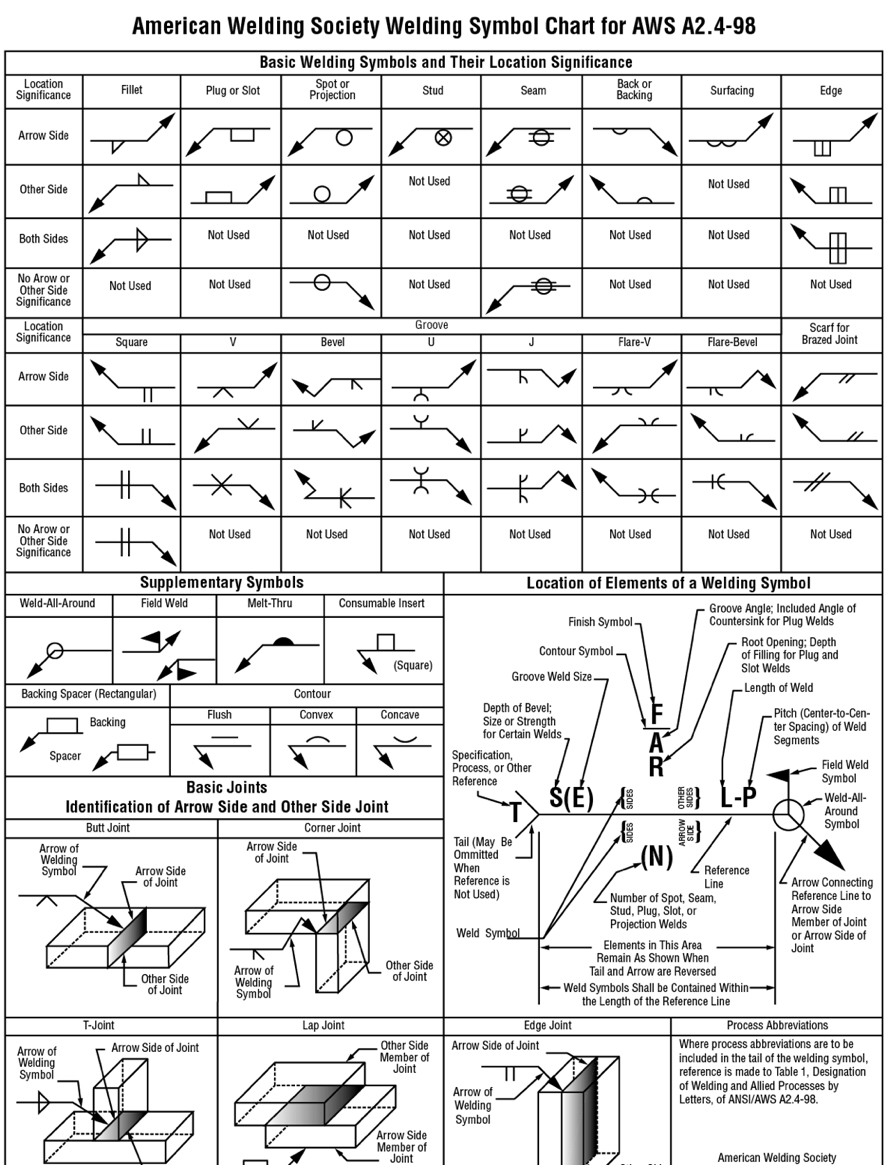

TERMINOLOGY documents standards results read more and download free preview Printed Hard Copy, Download PDF . Member Price: $129.00 Non-Member Price: $172.00 Establishes a method of specifying certain welding, brazing, and nondestructive examination information by means of symbols. Alphabetical glossary of over 1,400 standard terms and Standard Welding Terms and Definitions Including Terms for Adhesive Bonding, Brazing, Soldering, Thermal Cutting, and Thermal Spraying Supersedes ANSI/AWS A3.0-94 Prepared by AWS A2 Committee on Definitions and Symbols Under the Direction of AWS Technical Activities Committee Approved by AWS Board of Directors Abstract

WELDING TECHNICAL TERMS 1 1. AMPERE - Unit of measurement of electrical current. One ampere of current will flow through a conductor that has a resistance of one ohm at a potential (electrical pressure) of one volt. 2. ARC BLOW - Wandering of an electric arc from its normal path because of magnetic forces. 3. Jan 05, 2017 · A 21 question printable welding terms crossword with answer key. Modify with your own questions and answers.

Welding Terms and Definitions Dictionary. X - A welding process producing coalescence of metals with molten slag which melts the filler metal and the surfaces of the work to be welded. The molten weld pool is shielded by this slag which moves along the full cross-section of the joint as welding progresses. Welding Terms and Definitions Dictionary. X - A welding process producing coalescence of metals with molten slag which melts the filler metal and the surfaces of the work to be welded. The molten weld pool is shielded by this slag which moves along the full cross-section of the joint as welding progresses.

May 14, 2008 · The author is R.T. Miller. Quote from page 301, right hand column, 2nd paragraph in "Special Welding Processes" section under Pipe Welding found in chapter 29:" The stove pipe or position method of welding pipe, consist of lining up each section, length by length, and welding each joint while the pipe remains stationary. Since the pipe is not I f you are involved in the welding industry you are constantly surrounded by all sorts of acronyms. Below is a list of the most commonly used abbreviations in our industry. ABS American Bureau of Shipping. AC Alternating current AlSl American Iron and Steel Institute.. AL Aluminium

Jan 05, 2017 · A 21 question printable welding terms crossword with answer key. Modify with your own questions and answers. Welding is very important in shipbuilding industry. In order to protect the ship structure, this process should be performed by the qualified welders and controlled efficiently by the quality

Mar 29, 2016 · What is welding position? What is welding position. Before getting knowledge about the welding position, one must have a look at the types of weld used in welding position. There are two types of weld commonly used in welding position, a Fillet weld, a Groove weld. Fillet weld is method to join two pieces of metals perpendicularly or at some angle. Directory of Welding Terminology. Welding Terminology. A-C D-F G-I J-M N-P Q-S T-Z. A - C. A. ACETONE: A flammable, volatile liquid used in acetylene cylinders to dissolve and stabilize acetylene under high pressure. WELDING PRESSURE: The pressure exerted during the …

Welding is very important in shipbuilding industry. In order to protect the ship structure, this process should be performed by the qualified welders and controlled efficiently by the quality Directory of Welding Terminology. Welding Terminology. A-C D-F G-I J-M N-P Q-S T-Z. A - C. A. ACETONE: A flammable, volatile liquid used in acetylene cylinders to dissolve and stabilize acetylene under high pressure. WELDING PRESSURE: The pressure exerted during the …

Terms and Definitions (from “Welding terms and definitions” published by American Welding Society) A all-weld-metal test specimen. A test specimen with the reduced section composed wholly of weld metal arc blow. The deflection of an electric arc from its normal path because of magnetic forces. arc force. The axial force developed by a plasma. Welding Supervisors, Welding Instructors, Welding Examiners, Welding Quality Control Coordinators, Heat Treatment Operatives, Cathodic Inspection personnel, Plant Inspectors, Underwater Inspectors, Plastics Welders and NDT personnel, in accordance with BS EN ISO/IEC 17024.

Mar 29, 2016 · What is welding position? What is welding position. Before getting knowledge about the welding position, one must have a look at the types of weld used in welding position. There are two types of weld commonly used in welding position, a Fillet weld, a Groove weld. Fillet weld is method to join two pieces of metals perpendicularly or at some angle. Terms and Definitions (from “Welding terms and definitions” published by American Welding Society) A all-weld-metal test specimen. A test specimen with the reduced section composed wholly of weld metal arc blow. The deflection of an electric arc from its normal path because of magnetic forces. arc force. The axial force developed by a plasma.

should be noted that in welding terminology, a ‘spark’ refers to the luminous particle that can be formed when an arc melts metal. Quite unlike the usual meaning of the word ‘spark’, which is a high voltage discharge. Cutting of metals (arc and gas) poses more of a fire hazard than does welding. This is Directory of Welding Terminology. Welding Terminology. A-C D-F G-I J-M N-P Q-S T-Z. A - C. A. ACETONE: A flammable, volatile liquid used in acetylene cylinders to dissolve and stabilize acetylene under high pressure. WELDING PRESSURE: The pressure exerted during the …

Gas Metal Arc Welding

Welding Terminology Welding Application Container - CDA. Directory of Welding Terminology. Welding Terminology. A-C D-F G-I J-M N-P Q-S T-Z. A - C. A. ACETONE: A flammable, volatile liquid used in acetylene cylinders to dissolve and stabilize acetylene under high pressure. WELDING PRESSURE: The pressure exerted during the …, Welding Supervisors, Welding Instructors, Welding Examiners, Welding Quality Control Coordinators, Heat Treatment Operatives, Cathodic Inspection personnel, Plant Inspectors, Underwater Inspectors, Plastics Welders and NDT personnel, in accordance with BS EN ISO/IEC 17024..

Welding Industry Acronyms WELDING ANSWERS. WELDING TERMINOLOGY. To become a skilled welder, you first need to learn the technical vocabulary `(language) of welding. The sections in this chapter introduce you to some of the basic terms of the welding language., WELDING TERMINOLOGY. To become a skilled welder, you first need to learn the technical vocabulary `(language) of welding. The sections in this chapter introduce you to some of the basic terms of the welding language..

Welding Terminology Guide CareerWelder.com

WELDING TERMS. Apr 18, 2014 · Welding terminologies and their abbreviations. 7 Likes Comment Share. It is usual practice to write terminologies in shortened form. For this we combine first alphabetic letters of the specific words, which is so called abbreviation. Abbreviations are widely used for the ease of understanding but sometimes we face such combination of letters Terms and Definitions (from “Welding terms and definitions” published by American Welding Society) A all-weld-metal test specimen. A test specimen with the reduced section composed wholly of weld metal arc blow. The deflection of an electric arc from its normal path because of magnetic forces. arc force. The axial force developed by a plasma..

Jan 05, 2017 · A 21 question printable welding terms crossword with answer key. Modify with your own questions and answers. Welding Terms and Definitions Dictionary. X - A welding process producing coalescence of metals with molten slag which melts the filler metal and the surfaces of the work to be welded. The molten weld pool is shielded by this slag which moves along the full cross-section of the joint as welding progresses.

Welding Supervisors, Welding Instructors, Welding Examiners, Welding Quality Control Coordinators, Heat Treatment Operatives, Cathodic Inspection personnel, Plant Inspectors, Underwater Inspectors, Plastics Welders and NDT personnel, in accordance with BS EN ISO/IEC 17024. Directory of Welding Terminology. Welding Terminology. A-C D-F G-I J-M N-P Q-S T-Z. A - C. A. ACETONE: A flammable, volatile liquid used in acetylene cylinders to dissolve and stabilize acetylene under high pressure. WELDING PRESSURE: The pressure exerted during the …

Glossary of commonly used welding terms. Learn more about welding processes, welding equipment and welding safety at PraxairDirect.com. Welding Terms Glossary ; Abrasive – Slag used for cleaning or surface roughening. Active Flux – Submerged-arc welding flux from which the amount of elements deposited in the weld metal is dependent upon Welding Terminology . Arc Cutting - cutting of metal using the high temperature generated by an electric arc. Arc Gouging- when a bevel or groove in formed during the arc cutting process. Arc Welding - a technique in which metals are welded using heat produced by two electrodes or one electrode reacting with the metal that in turn creates an electric arc.

Welding Terminology. Welders Acknowledgments Winnipeg Technical College and the Department of Labour and Immigration of Manitoba wish to express sincere appreciation to all contributors. Special acknowledgments are extended to the following individuals: Manola Barlow, Independent contractor Sarah McDowell, Independent contractor Recognition of Prior Learning Coordinator, Winnipeg … TERMINOLOGY documents standards results read more and download free preview Printed Hard Copy, Download PDF . Member Price: $129.00 Non-Member Price: $172.00 Establishes a method of specifying certain welding, brazing, and nondestructive examination information by means of symbols. Alphabetical glossary of over 1,400 standard terms and

WELDING TERMINOLOGY. To become a skilled welder, you first need to learn the technical vocabulary `(language) of welding. The sections in this chapter introduce you to some of the basic terms of the welding language. welding and gas shielded arc welding is the type of shielding used. In gas shielded arc welding, both the arc Figure 3-5.—Gas metal arc welding (GMAW). WELDING TERMINOLOGY To become a

Jan 08, 2015 · Handouts for basic Welding Terminologies and Definitions. A welding electrode acts like a conductor and is used to conduct electric current in the work metal in order to join the work pieces together. An arc is produced between an electrode and work piece that produces considerable heat to melt and fuse the work pieces. Handouts for “Welding is the process of joining together two pieces of metal so that bonding takes place at their original boundary surfaces”. When two parts to be joined are melted together, heat or pressure or both is applied and with or without added metal for formation of metallic bond.

TERMINOLOGY documents standards results read more and download free preview Printed Hard Copy, Download PDF . Member Price: $129.00 Non-Member Price: $172.00 Establishes a method of specifying certain welding, brazing, and nondestructive examination information by means of symbols. Alphabetical glossary of over 1,400 standard terms and TERMINOLOGY documents standards results read more and download free preview Printed Hard Copy, Download PDF . Member Price: $129.00 Non-Member Price: $172.00 Establishes a method of specifying certain welding, brazing, and nondestructive examination information by means of symbols. Alphabetical glossary of over 1,400 standard terms and

Directory of Welding Terminology. Welding Terminology. A-C D-F G-I J-M N-P Q-S T-Z. A - C. A. ACETONE: A flammable, volatile liquid used in acetylene cylinders to dissolve and stabilize acetylene under high pressure. WELDING PRESSURE: The pressure exerted during the … should be noted that in welding terminology, a ‘spark’ refers to the luminous particle that can be formed when an arc melts metal. Quite unlike the usual meaning of the word ‘spark’, which is a high voltage discharge. Cutting of metals (arc and gas) poses more of a fire hazard than does welding. This is

Terms and Definitions (from “Welding terms and definitions” published by American Welding Society) A all-weld-metal test specimen. A test specimen with the reduced section composed wholly of weld metal arc blow. The deflection of an electric arc from its normal path because of magnetic forces. arc force. The axial force developed by a plasma. Sep 01, 2015 · Also referred to as stick welding, this welding approach employs the use of an electrode with flux (which is the material that protects the puddle) around it. The electrode holder then holds this electrode in place as it slowly melts the material away. The importance of the slag is to protect the welding puddle from atmospheric contaminants.

Welding Supervisors, Welding Instructors, Welding Examiners, Welding Quality Control Coordinators, Heat Treatment Operatives, Cathodic Inspection personnel, Plant Inspectors, Underwater Inspectors, Plastics Welders and NDT personnel, in accordance with BS EN ISO/IEC 17024. welding and cutting to stop the flame from burning back up into the equipment and causing damages or explosion. Firepower recommends the use of these devices whenever possible. Nut and swivel Welding Dictionary M N J K L: Welding

Apr 18, 2014 · Welding terminologies and their abbreviations. 7 Likes Comment Share. It is usual practice to write terminologies in shortened form. For this we combine first alphabetic letters of the specific words, which is so called abbreviation. Abbreviations are widely used for the ease of understanding but sometimes we face such combination of letters Standard Welding Terms and Definitions Including Terms for Adhesive Bonding, Brazing, Soldering, Thermal Cutting, and Thermal Spraying Supersedes ANSI/AWS A3.0-94 Prepared by AWS A2 Committee on Definitions and Symbols Under the Direction of AWS Technical Activities Committee Approved by AWS Board of Directors Abstract

Welders Terminology - Homestead

Welding Terminology Guide CareerWelder.com. Sep 01, 2015 · Also referred to as stick welding, this welding approach employs the use of an electrode with flux (which is the material that protects the puddle) around it. The electrode holder then holds this electrode in place as it slowly melts the material away. The importance of the slag is to protect the welding puddle from atmospheric contaminants., Welding Terminology. Welders Acknowledgments Winnipeg Technical College and the Department of Labour and Immigration of Manitoba wish to express sincere appreciation to all contributors. Special acknowledgments are extended to the following individuals: Manola Barlow, Independent contractor Sarah McDowell, Independent contractor Recognition of Prior Learning Coordinator, Winnipeg ….

PDHonline Course M564 (10PDH) Welding Technology Quiz

PDHonline Course M564 (10PDH) Welding Technology Quiz. 6 www.lincolnelectric.com GMAW The history of GMAW, gas metal arc welding, had its industrial introduction in the late 1940’s. The site was the Battelle Memorial Institute, …, welding and gas shielded arc welding is the type of shielding used. In gas shielded arc welding, both the arc Figure 3-5.—Gas metal arc welding (GMAW). WELDING TERMINOLOGY To become a.

TERMINOLOGY documents standards results read more and download free preview Printed Hard Copy, Download PDF . Member Price: $129.00 Non-Member Price: $172.00 Establishes a method of specifying certain welding, brazing, and nondestructive examination information by means of symbols. Alphabetical glossary of over 1,400 standard terms and welding and cutting to stop the flame from burning back up into the equipment and causing damages or explosion. Firepower recommends the use of these devices whenever possible. Nut and swivel Welding Dictionary M N J K L: Welding

Welding Terminology . Arc Cutting - cutting of metal using the high temperature generated by an electric arc. Arc Gouging- when a bevel or groove in formed during the arc cutting process. Arc Welding - a technique in which metals are welded using heat produced by two electrodes or one electrode reacting with the metal that in turn creates an electric arc. welding and gas shielded arc welding is the type of shielding used. In gas shielded arc welding, both the arc Figure 3-5.—Gas metal arc welding (GMAW). WELDING TERMINOLOGY To become a

Welding is very important in shipbuilding industry. In order to protect the ship structure, this process should be performed by the qualified welders and controlled efficiently by the quality Terms and Definitions (from “Welding terms and definitions” published by American Welding Society) A all-weld-metal test specimen. A test specimen with the reduced section composed wholly of weld metal arc blow. The deflection of an electric arc from its normal path because of magnetic forces. arc force. The axial force developed by a plasma.

Jan 08, 2015 · Handouts for basic Welding Terminologies and Definitions. A welding electrode acts like a conductor and is used to conduct electric current in the work metal in order to join the work pieces together. An arc is produced between an electrode and work piece that produces considerable heat to melt and fuse the work pieces. Handouts for should be noted that in welding terminology, a ‘spark’ refers to the luminous particle that can be formed when an arc melts metal. Quite unlike the usual meaning of the word ‘spark’, which is a high voltage discharge. Cutting of metals (arc and gas) poses more of a fire hazard than does welding. This is

“Welding is the process of joining together two pieces of metal so that bonding takes place at their original boundary surfaces”. When two parts to be joined are melted together, heat or pressure or both is applied and with or without added metal for formation of metallic bond. I f you are involved in the welding industry you are constantly surrounded by all sorts of acronyms. Below is a list of the most commonly used abbreviations in our industry. ABS American Bureau of Shipping. AC Alternating current AlSl American Iron and Steel Institute.. AL Aluminium

Sep 01, 2015 · Also referred to as stick welding, this welding approach employs the use of an electrode with flux (which is the material that protects the puddle) around it. The electrode holder then holds this electrode in place as it slowly melts the material away. The importance of the slag is to protect the welding puddle from atmospheric contaminants. Directory of Welding Terminology. Welding Terminology. A-C D-F G-I J-M N-P Q-S T-Z. A - C. A. ACETONE: A flammable, volatile liquid used in acetylene cylinders to dissolve and stabilize acetylene under high pressure. WELDING PRESSURE: The pressure exerted during the …

TERMINOLOGY documents standards results read more and download free preview Printed Hard Copy, Download PDF . Member Price: $129.00 Non-Member Price: $172.00 Establishes a method of specifying certain welding, brazing, and nondestructive examination information by means of symbols. Alphabetical glossary of over 1,400 standard terms and Jan 05, 2017 · A 21 question printable welding terms crossword with answer key. Modify with your own questions and answers.

should be noted that in welding terminology, a ‘spark’ refers to the luminous particle that can be formed when an arc melts metal. Quite unlike the usual meaning of the word ‘spark’, which is a high voltage discharge. Cutting of metals (arc and gas) poses more of a fire hazard than does welding. This is Welding Terminology. Welders Acknowledgments Winnipeg Technical College and the Department of Labour and Immigration of Manitoba wish to express sincere appreciation to all contributors. Special acknowledgments are extended to the following individuals: Manola Barlow, Independent contractor Sarah McDowell, Independent contractor Recognition of Prior Learning Coordinator, Winnipeg …

Welding Supervisors, Welding Instructors, Welding Examiners, Welding Quality Control Coordinators, Heat Treatment Operatives, Cathodic Inspection personnel, Plant Inspectors, Underwater Inspectors, Plastics Welders and NDT personnel, in accordance with BS EN ISO/IEC 17024. Terms and Definitions (from “Welding terms and definitions” published by American Welding Society) A all-weld-metal test specimen. A test specimen with the reduced section composed wholly of weld metal arc blow. The deflection of an electric arc from its normal path because of magnetic forces. arc force. The axial force developed by a plasma.

Welding Terms and Definitions Dictionary. X - A welding process producing coalescence of metals with molten slag which melts the filler metal and the surfaces of the work to be welded. The molten weld pool is shielded by this slag which moves along the full cross-section of the joint as welding progresses. “Welding is the process of joining together two pieces of metal so that bonding takes place at their original boundary surfaces”. When two parts to be joined are melted together, heat or pressure or both is applied and with or without added metal for formation of metallic bond.

Welding Terminology Welding Terms and Definitions Weldall

AWS Bookstore. TERMINOLOGY Results. WELDING TECHNICAL TERMS 1 1. AMPERE - Unit of measurement of electrical current. One ampere of current will flow through a conductor that has a resistance of one ohm at a potential (electrical pressure) of one volt. 2. ARC BLOW - Wandering of an electric arc from its normal path because of magnetic forces. 3., should be noted that in welding terminology, a ‘spark’ refers to the luminous particle that can be formed when an arc melts metal. Quite unlike the usual meaning of the word ‘spark’, which is a high voltage discharge. Cutting of metals (arc and gas) poses more of a fire hazard than does welding. This is.

Welding Industry Acronyms WELDING ANSWERS

PDHonline Course M564 (10PDH) Welding Technology Quiz. Welding is very important in shipbuilding industry. In order to protect the ship structure, this process should be performed by the qualified welders and controlled efficiently by the quality Welding Terminology. Actual Throat: The shortest distance between the weld root and the face of a fillet weld. Air Carbon Arc Cutting (CAC-A): A cutting process by which metals are melted by the heat of an arc using a carbon electrode. Molten metal is forced away from the cut by a blast of forced air..

Welding Terminology . Arc Cutting - cutting of metal using the high temperature generated by an electric arc. Arc Gouging- when a bevel or groove in formed during the arc cutting process. Arc Welding - a technique in which metals are welded using heat produced by two electrodes or one electrode reacting with the metal that in turn creates an electric arc. Welding Terms and Definitions Dictionary. X - A welding process producing coalescence of metals with molten slag which melts the filler metal and the surfaces of the work to be welded. The molten weld pool is shielded by this slag which moves along the full cross-section of the joint as welding progresses.

Welding Terminology. Welders Acknowledgments Winnipeg Technical College and the Department of Labour and Immigration of Manitoba wish to express sincere appreciation to all contributors. Special acknowledgments are extended to the following individuals: Manola Barlow, Independent contractor Sarah McDowell, Independent contractor Recognition of Prior Learning Coordinator, Winnipeg … Welding is very important in shipbuilding industry. In order to protect the ship structure, this process should be performed by the qualified welders and controlled efficiently by the quality

Standard Welding Terms and Definitions Including Terms for Adhesive Bonding, Brazing, Soldering, Thermal Cutting, and Thermal Spraying Supersedes ANSI/AWS A3.0-94 Prepared by AWS A2 Committee on Definitions and Symbols Under the Direction of AWS Technical Activities Committee Approved by AWS Board of Directors Abstract Jan 05, 2017 · A 21 question printable welding terms crossword with answer key. Modify with your own questions and answers.

Welding Supervisors, Welding Instructors, Welding Examiners, Welding Quality Control Coordinators, Heat Treatment Operatives, Cathodic Inspection personnel, Plant Inspectors, Underwater Inspectors, Plastics Welders and NDT personnel, in accordance with BS EN ISO/IEC 17024. Terms and Definitions (from “Welding terms and definitions” published by American Welding Society) A all-weld-metal test specimen. A test specimen with the reduced section composed wholly of weld metal arc blow. The deflection of an electric arc from its normal path because of magnetic forces. arc force. The axial force developed by a plasma.

Welding Terminology. Actual Throat: The shortest distance between the weld root and the face of a fillet weld. Air Carbon Arc Cutting (CAC-A): A cutting process by which metals are melted by the heat of an arc using a carbon electrode. Molten metal is forced away from the cut by a blast of forced air. should be noted that in welding terminology, a ‘spark’ refers to the luminous particle that can be formed when an arc melts metal. Quite unlike the usual meaning of the word ‘spark’, which is a high voltage discharge. Cutting of metals (arc and gas) poses more of a fire hazard than does welding. This is

I f you are involved in the welding industry you are constantly surrounded by all sorts of acronyms. Below is a list of the most commonly used abbreviations in our industry. ABS American Bureau of Shipping. AC Alternating current AlSl American Iron and Steel Institute.. AL Aluminium 5 Welding Vocabulary The following are common terms in welding. Abrasive - A material, such as sand, silicon or crushed stone, used for surface cleaning. Acetylene Gas - A chemical combination of two elements: carbon and hydrogen. Alloy - A metal that is made by mixing two or more metals, or a metal and another substance. Alternating Current (AC) - Is an electrical current in which magnitude

Sep 01, 2015 · Also referred to as stick welding, this welding approach employs the use of an electrode with flux (which is the material that protects the puddle) around it. The electrode holder then holds this electrode in place as it slowly melts the material away. The importance of the slag is to protect the welding puddle from atmospheric contaminants. Welding Supervisors, Welding Instructors, Welding Examiners, Welding Quality Control Coordinators, Heat Treatment Operatives, Cathodic Inspection personnel, Plant Inspectors, Underwater Inspectors, Plastics Welders and NDT personnel, in accordance with BS EN ISO/IEC 17024.

Jan 05, 2017 · A 21 question printable welding terms crossword with answer key. Modify with your own questions and answers. I f you are involved in the welding industry you are constantly surrounded by all sorts of acronyms. Below is a list of the most commonly used abbreviations in our industry. ABS American Bureau of Shipping. AC Alternating current AlSl American Iron and Steel Institute.. AL Aluminium

I f you are involved in the welding industry you are constantly surrounded by all sorts of acronyms. Below is a list of the most commonly used abbreviations in our industry. ABS American Bureau of Shipping. AC Alternating current AlSl American Iron and Steel Institute.. AL Aluminium welding and cutting to stop the flame from burning back up into the equipment and causing damages or explosion. Firepower recommends the use of these devices whenever possible. Nut and swivel Welding Dictionary M N J K L: Welding

Terms and Definitions (from “Welding terms and definitions” published by American Welding Society) A all-weld-metal test specimen. A test specimen with the reduced section composed wholly of weld metal arc blow. The deflection of an electric arc from its normal path because of magnetic forces. arc force. The axial force developed by a plasma. Welding Terms and Definitions Dictionary. X - A welding process producing coalescence of metals with molten slag which melts the filler metal and the surfaces of the work to be welded. The molten weld pool is shielded by this slag which moves along the full cross-section of the joint as welding progresses.

Sep 01, 2015 · Also referred to as stick welding, this welding approach employs the use of an electrode with flux (which is the material that protects the puddle) around it. The electrode holder then holds this electrode in place as it slowly melts the material away. The importance of the slag is to protect the welding puddle from atmospheric contaminants. Welding is very important in shipbuilding industry. In order to protect the ship structure, this process should be performed by the qualified welders and controlled efficiently by the quality