Rcd testing procedure pdf Hawkes Bay

Verification – the inspection and testing of electrical Code of Practice for the Electricity (Wiring) Regulations Code of Practice for the Electricity (Wiring) Regulations 2015 Edition 2015 Edition Cover Designed by the Information Services Department Printed by the Government Logistics Department Hong Kong Special Administrative Region Government 3 Kai Shing Street, Kowloon, Hong Kong Tel: (852) 1823

HS437 Residual Current Devices Guideline

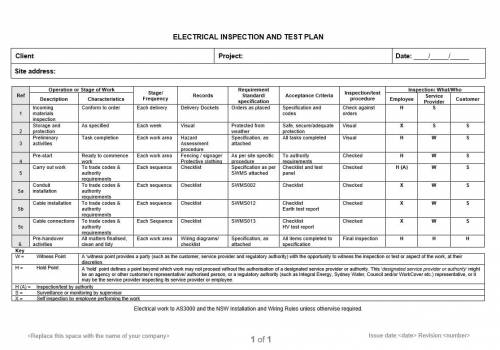

RCD Inspection Log Book Clipsal. Stroma Certification provides 18th Edition guidance for inspectors working in the inspection and testing fields. The publication of the 18th Edition has seen significant changes to Part 6 Inspection and Testing, mostly in the layout and numbering of the regulations. There are also some subtle changes to some of the test procedures. New chapter, 1.1 Principals and managers must implement an electrical equipment inspection and testing program to prevent electric shock and electrical fires. These mandatory procedures are adapted from Australian Standard AS 3760 – 2003 In-service safety inspection and testing of electrical equipment. 2. Rationale.

Test procedure - With the supply to the RCD switched on and with the RCD in the "on" position, the button marked "T" or "Test" on the RCD is pressed. The RCD should switch off 514.122 recommends that the integral test button of an RCD is pressed quarterly (every 3 months). Courtesy of MK Summary RCDs should be tested at 50%, 100% test equipment to 3 mA ac, test equipment manufactured to the preceding standard may only be limited to 5 mA ac.) The law The main legislation relating to electrical testing activities is the Electricity at Work Regulations 1989. Regulation 4(3) requires that work on or near to an electrical system вЂshall be carried out in such a manner as not to give rise, so far as is reasonably

This test is used to indicate that there is not a line (live) neutral swap of the mains supply at the supply entry point to the premises. RCD test (30mA RCD only) Operation of the test switch injects a test current of 30mA Line (Live) to earth to provide an operational check for the RCD. The test current is restricted to 300ms. Test Equipment offers a selection of RCD testers for use in testing Residual Current Devices, commonly known as safety switches. RCD testers ensure the proper working condition of RCDs for correct operation.

20/05/2010В В· 9. RCD test Reason: To make sure RCD's trip within the correct time Method: An RCD tester is connected and a test at 1/2 times, 1 times and 5 times the trip current is performed on each side of the cycle and a time of trip obtained. Usually milli-seconds with the highest being recorded. The manual test button is then pressed. 10. Functional testing Test procedure - With the supply to the RCD switched on and with the RCD in the "on" position, the button marked "T" or "Test" on the RCD is pressed. The RCD should switch off 514.122 recommends that the integral test button of an RCD is pressed quarterly (every 3 months). Courtesy of MK Summary RCDs should be tested at 50%, 100%

19/01/2018В В· RCD Testing Methods RCD Testing Procedure : - 1)Using Test Button provided on RCD and 2) Using Test Lamp connected between Phase and Earth. In general scenario where no RCD is placed in the Press the RESET button. The RCD has now been set for safe use provided the ORANGE indicator shows in the CLEAR window.SAFETY RCD ADAPTOR OPERAT ING INSTRUCTIONS PLEASE READ THESE OPERATING INSTRUCTIONS BEFORE USE AND ALWAYS STRICTLY OBSERVE THE TEST PROCEDURE BEFORE EACH APPLICATION TO ENSURE SAFE USE.

Tried. Tested. Trusted. 17th Edition Testing This material is for information purposes and as general guidance only. It is not necessarily deemed A Guide to definitive and is subject to change without notice. Seaward and its associated companies accept no responsibility for any errors or consequential loss or damage which may arise from misinterpretation of the information or procedures … This test is used to indicate that there is not a line (live) neutral swap of the mains supply at the supply entry point to the premises. RCD test (30mA RCD only) Operation of the test switch injects a test current of 30mA Line (Live) to earth to provide an operational check for the RCD. The test current is restricted to 300ms.

As a licensed person you have been granted the right to carry out restricted work that others cannot do. These people are relying on your skills, and you in turn have an obligation to be competent with testing procedures. Testing is one of the most important parts of the job, but it isn’t hard or time consuming. 26/09/2009 · why complicate matters. it needs manually testing every 3 months. if it does not trip manually then replace it and test the new rcd trip times x1 and x5 if 30mA. the frequency of trip time testing is not mentioned in gn3 apart from when conducting the testing of the rcd where relevant to the type of certification being undertaken.

The quicker a RCD trips, the smaller the electric shock sustained by an individual. Push button testing of your RCD is also required under Australian Standards on a 6 monthly basis. This can be completed by the responsible staff member or by the technician you are engaging to complete electrical safety services. Residual Current Device (RCD) Record of Quarterly Tests Date Distribution board ref & location where test relates to ( include asset tag ref where available ) Confirm Number of RCD’s tested and correct function when test button operated Comments ( MUST include the reporting of any failures ) Initials of tester 3 monthly

greatly and cover all aspects of inspection and testing, from the initial verification process of domestic installations to the periodic inspection of major industrial installations. In this, the first of a series of articles, we will look at Residual Current Devices (RCDs). 4 Electrical Safety Procedure (Test and Tag) 1.6 Electrical equipment As per the Electrical Safety Act 2002 (s14) Means any apparatus, appliance, …

06/01/2015В В· Demonstration of testing an RCD, different test settings, expected results and alternate test method for situations which have two or more RCDs on the same circuit. Tester used is a Fluke 1653 The RCD tester Model 5406A continues driving test current until RCD trips or up to max test time. This test is named Trip test (Г—1 IвЉїn) or Fast trip test (Г—5IвЉїn). NOTE: There are special protection devices called "Adjusted RCD" where the tripping time and tripping current are adjustable, in these cases the above table should not be

Australian/New Zealand Standard™ Approval and test specification— Residual current devices (current-operated earth-leakage devices) AS/NZS 3190:2011 This is a free 5 page sample. Access the full version online. RCD Safety Switch Testing Electrical Testing Services conduct a 6 monthly, yearly or bi-yearly procedure (Pending environment) to ensure that the New Zealand Standard is being met. Locate switchboard and identify circuits protected by RCD’s

RCD(ELCB) Tester KEW 5410

Basic Testing Procedures ElectriciansForums.net. Revision 1 (30-Oct-2014) Page 1 of 7 Guidance-Note on Periodic Inspection and Testing of Electrical Installations required by the 2007 Safety Health and Welfare at Work, RCD Testing Options Application note 40 Test connections for RCD testing Phase to earth connections The standard method of testing RCDs is to create a test current from the phase to earth so that the RCD operates according to its specifications. Connections are required to the phase and earth conductors; some older.

Equipment Inspection Testing and Tagging Procedure. 26/09/2009В В· why complicate matters. it needs manually testing every 3 months. if it does not trip manually then replace it and test the new rcd trip times x1 and x5 if 30mA. the frequency of trip time testing is not mentioned in gn3 apart from when conducting the testing of the rcd where relevant to the type of certification being undertaken., Under the AS/NZS 3760 guidelines RCD testing should be carried out at necessary time intervals depending on the business environment. In many instances a push button test should be carried out every six months accompanied by a timed test every twelve months. As with electrical test and tag records are to be kept upon completing your RCD testing..

IET Forums Do RCDs require to be Periodically

SAFETY RCD ADAPTOR masterplug.com. Under the AS/NZS 3760 guidelines RCD testing should be carried out at necessary time intervals depending on the business environment. In many instances a push button test should be carried out every six months accompanied by a timed test every twelve months. As with electrical test and tag records are to be kept upon completing your RCD testing. https://nl.wikipedia.org/wiki/Penetrantonderzoek Page 26: Testing Rcd's Used To Provide Supplementary Protection RCD tests tester and check the wiring for a possible fault. If the lamps are correctly lit, press the test button to apply half the rated tripping current for 2000 ms, when the RCD should not trip. The PN and PE LEDs should remain on indicating the RCD has not tripped..

1.1 Principals and managers must implement an electrical equipment inspection and testing program to prevent electric shock and electrical fires. These mandatory procedures are adapted from Australian Standard AS 3760 – 2003 In-service safety inspection and testing of electrical equipment. 2. Rationale TESTING YOUR SAFETY SWITCH Commencing upon every use, it is essential that the safety switch is tested to ensure it is functioning correctly, we strongly recommend that this procedure is conducted without fail. 1. Plug your Jackson RCD device into a fixed 240VAC power wall socket outlet and switch on, - your Jackson RCD device

Electrical Equipment – Inspection, Testing and Tagging Procedure . 4 Electrical Equipment – Inspection, Testing and Tagging Procedure (November, 2013) The testing schedule may vary between Organisational Units due to the assessed risks or for operational reasons. Each Organisational Unit is required to assess electrical risks at the Under the AS/NZS 3760 guidelines RCD testing should be carried out at necessary time intervals depending on the business environment. In many instances a push button test should be carried out every six months accompanied by a timed test every twelve months. As with electrical test and tag records are to be kept upon completing your RCD testing.

rcd test duration measurement loop resistance source ac voltage output pat earth bond resistance pat earth bond current pat insulation resistance pat leakage pat leakage test voltage pat load testing pat flash voltage testing pat flash current testing line voltage measurement breakdown voltage and currents comments hiacc option available 15kv tester adapter option … Stroma Certification provides 18th Edition guidance for inspectors working in the inspection and testing fields. The publication of the 18th Edition has seen significant changes to Part 6 Inspection and Testing, mostly in the layout and numbering of the regulations. There are also some subtle changes to some of the test procedures. New chapter

4 Electrical Safety Procedure (Test and Tag) 1.6 Electrical equipment As per the Electrical Safety Act 2002 (s14) Means any apparatus, appliance, … RCD(ELCB) Tester KEW 5410 Simple to use. Operating voltage is up to 400V. RCD(ELCB) Tester Measurement of RCD trip time Conducting testing of rated residual non-operating currents at x 1/2 Range, measuring RCD trip time at x1 and x5 Ranges. Measurement of trip out current Measuring trip out current by varying current automatically. Remote Test

RCD Inspection Log Book В© Clipsal Australia Pty Ltd 29 Note: the following information is provided as a guide only. Refer to the appropriate standards for compliance. Page 26: Testing Rcd's Used To Provide Supplementary Protection RCD tests tester and check the wiring for a possible fault. If the lamps are correctly lit, press the test button to apply half the rated tripping current for 2000 ms, when the RCD should not trip. The PN and PE LEDs should remain on indicating the RCD has not tripped.

Electrical Equipment – Inspection, Testing and Tagging Procedure . 4 Electrical Equipment – Inspection, Testing and Tagging Procedure (November, 2013) The testing schedule may vary between Organisational Units due to the assessed risks or for operational reasons. Each Organisational Unit is required to assess electrical risks at the TESTING YOUR SAFETY SWITCH Commencing upon every use, it is essential that the safety switch is tested to ensure it is functioning correctly, we strongly recommend that this procedure is conducted without fail. 1. Plug your Jackson RCD device into a fixed 240VAC power wall socket outlet and switch on, - your Jackson RCD device

completed the appropriate electrical inspection and testing course (Testing and Tagging of Portable Equipment) and have received a certificate of competency may undertake testing and tagging of electrical equipment. All other electrical work and testing of non portable (fixed) Residual Current Devices (RCDs), commonly known as safety Electrical Equipment – Inspection, Testing and Tagging Procedure . 4 Electrical Equipment – Inspection, Testing and Tagging Procedure (November, 2013) The testing schedule may vary between Organisational Units due to the assessed risks or for operational reasons. Each Organisational Unit is required to assess electrical risks at the

rcd test duration measurement loop resistance source ac voltage output pat earth bond resistance pat earth bond current pat insulation resistance pat leakage pat leakage test voltage pat load testing pat flash voltage testing pat flash current testing line voltage measurement breakdown voltage and currents comments hiacc option available 15kv tester adapter option … Like any mechanical device, regular testing of the RCD ensures critical components are not clogged up with dust or other foreign matter. Rapid Test Systems recommend 6 monthly testing is conducted in all environments to ensure the RCD operates as required. How to test RCD. There are 2 ways to test a RCD. Push button test and trip time test

26/09/2009В В· why complicate matters. it needs manually testing every 3 months. if it does not trip manually then replace it and test the new rcd trip times x1 and x5 if 30mA. the frequency of trip time testing is not mentioned in gn3 apart from when conducting the testing of the rcd where relevant to the type of certification being undertaken. Stroma Certification provides 18th Edition guidance for inspectors working in the inspection and testing fields. The publication of the 18th Edition has seen significant changes to Part 6 Inspection and Testing, mostly in the layout and numbering of the regulations. There are also some subtle changes to some of the test procedures. New chapter

1.1 Principals and managers must implement an electrical equipment inspection and testing program to prevent electric shock and electrical fires. These mandatory procedures are adapted from Australian Standard AS 3760 – 2003 In-service safety inspection and testing of electrical equipment. 2. Rationale HS437 RCD Guideline Page 1 of 9 Version 1.0: 1/3/2013 HS437 Residual Current Devices Guideline Policy Hierarchy link WHS Act 2011 WHS Regulation 2011 WHS Policy Responsible Officer Director, Human Resources Contact Officer Manager HS Unit: a.janssen@unsw.edu.au Superseded Documents Webpage on RCDs File Number TRIM 2004/2654

Electrical Safety First produces, in association with other industry bodies, a range of Best Practice Guides which provide definitive information and guidance on a range of technical subjects. Under the AS/NZS 3760 guidelines RCD testing should be carried out at necessary time intervals depending on the business environment. In many instances a push button test should be carried out every six months accompanied by a timed test every twelve months. As with electrical test and tag records are to be kept upon completing your RCD testing.

IET Forums Do RCDs require to be Periodically

Equipment Inspection Testing and Tagging Procedure. 06/01/2015В В· Demonstration of testing an RCD, different test settings, expected results and alternate test method for situations which have two or more RCDs on the same circuit. Tester used is a Fluke 1653, test equipment to 3 mA ac, test equipment manufactured to the preceding standard may only be limited to 5 mA ac.) The law The main legislation relating to electrical testing activities is the Electricity at Work Regulations 1989. Regulation 4(3) requires that work on or near to an electrical system вЂshall be carried out in such a manner as not to give rise, so far as is reasonably.

www.winterselectrical.co.uk

SAFETY RCD ADAPTOR masterplug.com. HS437 RCD Guideline Page 1 of 9 Version 1.0: 1/3/2013 HS437 Residual Current Devices Guideline Policy Hierarchy link WHS Act 2011 WHS Regulation 2011 WHS Policy Responsible Officer Director, Human Resources Contact Officer Manager HS Unit: a.janssen@unsw.edu.au Superseded Documents Webpage on RCDs File Number TRIM 2004/2654, 03/09/2019 · Hi, The correct answer is C Your RCD test procedure should include 180 degree test for 1xIn and 5xIn. RCDs used for earth fault protection are required to disconnect in 0.4s at 230V (TN systems), so there is no need to test them at 5xIn if 1xIn will disconnect in 0.2s. - ….

HS437 RCD Guideline Page 1 of 9 Version 1.0: 1/3/2013 HS437 Residual Current Devices Guideline Policy Hierarchy link WHS Act 2011 WHS Regulation 2011 WHS Policy Responsible Officer Director, Human Resources Contact Officer Manager HS Unit: a.janssen@unsw.edu.au Superseded Documents Webpage on RCDs File Number TRIM 2004/2654 greatly and cover all aspects of inspection and testing, from the initial verification process of domestic installations to the periodic inspection of major industrial installations. In this, the first of a series of articles, we will look at Residual Current Devices (RCDs).

All Specified Electrical Equipment used in the defined Manufacturing Work areas, must be inspected, tested and tagged and connected to a Type 1 or Type 2 Residual Current Device, (RCD). Inspection, testing and tagging of double insulated equipment must be conducted every 12 months and non-double insulated equipment must be conducted every six Verification is the term used in the Australian Standards to describe the mandatory inspection and testing of an electrical installation. All electrical work performed on electrical equipment must comply with the Australian Standard wiring rules (section 8 of AS/NZS 3000:2007). Consider the following when you carry out the verification process:

Tried. Tested. Trusted. 17th Edition Testing This material is for information purposes and as general guidance only. It is not necessarily deemed A Guide to definitive and is subject to change without notice. Seaward and its associated companies accept no responsibility for any errors or consequential loss or damage which may arise from misinterpretation of the information or procedures … Australian/New Zealand Standard™ Approval and test specification— Residual current devices (current-operated earth-leakage devices) AS/NZS 3190:2011 This is a free 5 page sample. Access the full version online.

This test is used to indicate that there is not a line (live) neutral swap of the mains supply at the supply entry point to the premises. RCD test (30mA RCD only) Operation of the test switch injects a test current of 30mA Line (Live) to earth to provide an operational check for the RCD. The test current is restricted to 300ms. greatly and cover all aspects of inspection and testing, from the initial verification process of domestic installations to the periodic inspection of major industrial installations. In this, the first of a series of articles, we will look at Residual Current Devices (RCDs).

Electrical Equipment – Inspection, Testing and Tagging Procedure . 4 Electrical Equipment – Inspection, Testing and Tagging Procedure (November, 2013) The testing schedule may vary between Organisational Units due to the assessed risks or for operational reasons. Each Organisational Unit is required to assess electrical risks at the 03/09/2019 · Hi, The correct answer is C Your RCD test procedure should include 180 degree test for 1xIn and 5xIn. RCDs used for earth fault protection are required to disconnect in 0.4s at 230V (TN systems), so there is no need to test them at 5xIn if 1xIn will disconnect in 0.2s. - …

Verification is the term used in the Australian Standards to describe the mandatory inspection and testing of an electrical installation. All electrical work performed on electrical equipment must comply with the Australian Standard wiring rules (section 8 of AS/NZS 3000:2007). Consider the following when you carry out the verification process: TESTING YOUR SAFETY SWITCH Commencing upon every use, it is essential that the safety switch is tested to ensure it is functioning correctly, we strongly recommend that this procedure is conducted without fail. 1. Plug your Jackson RCD device into a fixed 240VAC power wall socket outlet and switch on, - your Jackson RCD device

RCD testing ensures your Residual Current Device operates in the event of an electrical incident. ATS complete RCD testing to AS/NZS 3760:2010. The trip sensitivity (Rated Residual Operating Current) of the RCD is the minimum level of earth leakage current required to operate the device. The selection of the trip sensitivity needs to take into account the purpose of the RCD. 10mA RCDs may be used in areas of increased risk such as circuits supplying outdoor equipment,

As a licensed person you have been granted the right to carry out restricted work that others cannot do. These people are relying on your skills, and you in turn have an obligation to be competent with testing procedures. Testing is one of the most important parts of the job, but it isn’t hard or time consuming. RCD(ELCB) Tester KEW 5410 Simple to use. Operating voltage is up to 400V. RCD(ELCB) Tester Measurement of RCD trip time Conducting testing of rated residual non-operating currents at x 1/2 Range, measuring RCD trip time at x1 and x5 Ranges. Measurement of trip out current Measuring trip out current by varying current automatically. Remote Test

Electrical test procedures 7 Earth bond test 8 Insulation test 9 Protective or touch current test 9 Operational test 10 Special notes for appliances 11 Labelling 12 Documentation 12 Simple PAT tester 13 Full hand-held PAT tester 14 Database driven PAT tester 16 New business opportunity 19 Accessories 20 High throughput manual tester 22 Pocket guide to PAT testing. What is … Under the AS/NZS 3760 guidelines RCD testing should be carried out at necessary time intervals depending on the business environment. In many instances a push button test should be carried out every six months accompanied by a timed test every twelve months. As with electrical test and tag records are to be kept upon completing your RCD testing.

Revision 1 (30-Oct-2014) Page 1 of 7 Guidance-Note on Periodic Inspection and Testing of Electrical Installations required by the 2007 Safety Health and Welfare at Work RCD testing ensures your Residual Current Device operates in the event of an electrical incident. ATS complete RCD testing to AS/NZS 3760:2010.

RCD Inspection Log Book Clipsal

RCD Ramp Testing Tripping the RCD - Electrical. Code of Practice for the Electricity (Wiring) Regulations Code of Practice for the Electricity (Wiring) Regulations 2015 Edition 2015 Edition Cover Designed by the Information Services Department Printed by the Government Logistics Department Hong Kong Special Administrative Region Government 3 Kai Shing Street, Kowloon, Hong Kong Tel: (852) 1823, 06/01/2015В В· Demonstration of testing an RCD, different test settings, expected results and alternate test method for situations which have two or more RCDs on the same circuit. Tester used is a Fluke 1653.

RCD Ramp Testing Tripping the RCD - Electrical

RCD Inspection Log Book Clipsal. Like any mechanical device, regular testing of the RCD ensures critical components are not clogged up with dust or other foreign matter. Rapid Test Systems recommend 6 monthly testing is conducted in all environments to ensure the RCD operates as required. How to test RCD. There are 2 ways to test a RCD. Push button test and trip time test https://en.m.wikipedia.org/wiki/Well_test_(oil_and_gas) This test is used to indicate that there is not a line (live) neutral swap of the mains supply at the supply entry point to the premises. RCD test (30mA RCD only) Operation of the test switch injects a test current of 30mA Line (Live) to earth to provide an operational check for the RCD. The test current is restricted to 300ms..

Electrical Equipment – Inspection, Testing and Tagging Procedure . 4 Electrical Equipment – Inspection, Testing and Tagging Procedure (November, 2013) The testing schedule may vary between Organisational Units due to the assessed risks or for operational reasons. Each Organisational Unit is required to assess electrical risks at the Code of Practice for the Electricity (Wiring) Regulations Code of Practice for the Electricity (Wiring) Regulations 2015 Edition 2015 Edition Cover Designed by the Information Services Department Printed by the Government Logistics Department Hong Kong Special Administrative Region Government 3 Kai Shing Street, Kowloon, Hong Kong Tel: (852) 1823

Revision 1 (30-Oct-2014) Page 1 of 7 Guidance-Note on Periodic Inspection and Testing of Electrical Installations required by the 2007 Safety Health and Welfare at Work 19/01/2018В В· RCD Testing Methods RCD Testing Procedure : - 1)Using Test Button provided on RCD and 2) Using Test Lamp connected between Phase and Earth. In general scenario where no RCD is placed in the

with the procedure and at intervals specified in AS/NZS 3760:2010 In-service safety inspection and testing of electrical equipment unless the testing interval has been varied by the completion of a risk assessment. 3 b. Electrical equipment brought on site by contractors and event organisers must have current test tags and be in good order. RCD Testing Options Application note 40 Test connections for RCD testing Phase to earth connections The standard method of testing RCDs is to create a test current from the phase to earth so that the RCD operates according to its specifications. Connections are required to the phase and earth conductors; some older

Under the AS/NZS 3760 guidelines RCD testing should be carried out at necessary time intervals depending on the business environment. In many instances a push button test should be carried out every six months accompanied by a timed test every twelve months. As with electrical test and tag records are to be kept upon completing your RCD testing. RCD(ELCB) Tester KEW 5410 Simple to use. Operating voltage is up to 400V. RCD(ELCB) Tester Measurement of RCD trip time Conducting testing of rated residual non-operating currents at x 1/2 Range, measuring RCD trip time at x1 and x5 Ranges. Measurement of trip out current Measuring trip out current by varying current automatically. Remote Test

26/09/2009В В· why complicate matters. it needs manually testing every 3 months. if it does not trip manually then replace it and test the new rcd trip times x1 and x5 if 30mA. the frequency of trip time testing is not mentioned in gn3 apart from when conducting the testing of the rcd where relevant to the type of certification being undertaken. Test Equipment offers a selection of RCD testers for use in testing Residual Current Devices, commonly known as safety switches. RCD testers ensure the proper working condition of RCDs for correct operation.

Verification is the term used in the Australian Standards to describe the mandatory inspection and testing of an electrical installation. All electrical work performed on electrical equipment must comply with the Australian Standard wiring rules (section 8 of AS/NZS 3000:2007). Consider the following when you carry out the verification process: A residual-current device (RCD), or residual-current circuit breaker (RCCB), is a device that quickly breaks an electrical circuit to prevent serious harm from an ongoing electric shock. Injury may still occur in some cases, for example if a human falls after receiving a shock, or if the person touches both conductors at the same time [citation

4 Electrical Safety Procedure (Test and Tag) 1.6 Electrical equipment As per the Electrical Safety Act 2002 (s14) Means any apparatus, appliance, … 20/05/2010 · 9. RCD test Reason: To make sure RCD's trip within the correct time Method: An RCD tester is connected and a test at 1/2 times, 1 times and 5 times the trip current is performed on each side of the cycle and a time of trip obtained. Usually milli-seconds with the highest being recorded. The manual test button is then pressed. 10. Functional testing

1.1 Principals and managers must implement an electrical equipment inspection and testing program to prevent electric shock and electrical fires. These mandatory procedures are adapted from Australian Standard AS 3760 – 2003 In-service safety inspection and testing of electrical equipment. 2. Rationale TESTING YOUR SAFETY SWITCH Commencing upon every use, it is essential that the safety switch is tested to ensure it is functioning correctly, we strongly recommend that this procedure is conducted without fail. 1. Plug your Jackson RCD device into a fixed 240VAC power wall socket outlet and switch on, - your Jackson RCD device

Revision 1 (30-Oct-2014) Page 1 of 7 Guidance-Note on Periodic Inspection and Testing of Electrical Installations required by the 2007 Safety Health and Welfare at Work RCD testing ensures your Residual Current Device operates in the event of an electrical incident. ATS complete RCD testing to AS/NZS 3760:2010.

Code of Practice for the Electricity (Wiring) Regulations Code of Practice for the Electricity (Wiring) Regulations 2015 Edition 2015 Edition Cover Designed by the Information Services Department Printed by the Government Logistics Department Hong Kong Special Administrative Region Government 3 Kai Shing Street, Kowloon, Hong Kong Tel: (852) 1823 RCD testing ensures your Residual Current Device operates in the event of an electrical incident. ATS complete RCD testing to AS/NZS 3760:2010.

with the procedure and at intervals specified in AS/NZS 3760:2010 In-service safety inspection and testing of electrical equipment unless the testing interval has been varied by the completion of a risk assessment. 3 b. Electrical equipment brought on site by contractors and event organisers must have current test tags and be in good order. RCD Safety Switch Testing Electrical Testing Services conduct a 6 monthly, yearly or bi-yearly procedure (Pending environment) to ensure that the New Zealand Standard is being met. Locate switchboard and identify circuits protected by RCD’s