The manual transmission shifter assembly is a central component enabling precise gear control‚ essential for smooth vehicle operation and driver command over transmission performance.

1.1 Overview of Manual Transmission Systems

A manual transmission system‚ operated via a clutch pedal and gear shifter‚ allows drivers to control gear changes mechanically. The shifter assembly connects to the transmission‚ enabling precise gear selection. This system requires driver input for smooth acceleration and deceleration‚ enhancing control and driving engagement. The manual transmission’s design ensures efficiency and driver connection‚ making it a preferred choice for performance and fuel economy in various vehicles.

1.2 Importance of the Shifter Assembly in Vehicle Performance

The shifter assembly is crucial for optimal vehicle performance‚ enabling smooth and precise gear transitions. It connects the driver’s input to the transmission‚ ensuring accurate control over speed and torque delivery. A well-functioning shifter enhances driving experience by providing tactile feedback and reducing mechanical wear. Its reliability directly impacts acceleration‚ fuel efficiency‚ and overall vehicle responsiveness‚ making it a vital component for both everyday driving and high-performance applications.

Components of the Manual Transmission Shifter Assembly

The manual transmission shifter assembly consists of key components such as the shift lever‚ shift knob‚ boot‚ linkage‚ and cables. These parts work together to facilitate smooth and precise gear changes‚ ensuring efficient transmission control and optimal driving performance.

2.1 Shift Lever and Its Function

The shift lever is a crucial component in the manual transmission shifter assembly‚ serving as the direct interface between the driver and the transmission. It translates the driver’s movements into precise gear changes by engaging the transmission’s internal mechanisms; The lever’s design‚ including its length and material‚ impacts shifting smoothness and effort. Proper alignment and adjustment ensure accurate gear selection‚ while wear or misalignment can lead to shifting issues. The shift lever’s functionality is essential for maintaining control over the vehicle’s speed and torque delivery‚ making it integral to the driving experience.

2.2 Shift Knob and Boot Design

The shift knob and boot are essential components of the shifter assembly‚ providing a comfortable and durable interface for the driver. The shift knob is designed for grip and control‚ often made from materials like leather‚ rubber‚ or aluminum‚ while the boot protects the shift lever from dust and debris. Custom designs and aftermarket options allow for personalized style and enhanced tactile feedback‚ improving the overall driving experience. Proper fitment ensures smooth operation and longevity of the shifter assembly.

2.3 Linkage and Cables in the Shifter Assembly

The linkage and cables within the shifter assembly are critical for transmitting gear shift inputs to the transmission. These components ensure precise alignment and smooth movement‚ allowing drivers to engage gears effectively. High-quality materials and proper tensioning are vital to prevent wear and tear‚ which can lead to shifting issues. Regular maintenance and inspection of these parts are essential to maintain optimal performance and avoid costly repairs down the line.

How the Manual Transmission Shifter Assembly Works

The manual transmission shifter assembly translates driver input into precise gear changes by mechanically linking the shift lever to the transmission‚ enabling smooth gear engagement and ratio selection.

3.1 Mechanical Linkage and Gear Shifting Process

The mechanical linkage in a manual transmission shifter assembly connects the shift lever to the transmission‚ enabling precise gear changes. When the driver moves the lever‚ it actuates the linkage‚ translating the motion into gear engagement. This process relies on components like shift knobs and boots for smooth operation. High-quality shifters‚ such as those from Hurst or B&M‚ ensure durability and control‚ making the shifting process efficient and responsive to driver input.

3.2 Role of the Clutch Pedal in Shifter Operation

The clutch pedal is essential for disconnecting the engine from the transmission during gear shifts. Pressing the pedal disengages the engine‚ allowing the driver to shift gears without grinding. Releasing the pedal reconnects the engine‚ ensuring smooth power delivery. The clutch pedal works in harmony with the shifter assembly‚ enabling precise control over gear transitions. Proper synchronization is critical for efficient shifting‚ making the clutch pedal a vital component in manual transmission operation.

Types of Manual Transmission Shifter Assemblies

Manual transmission shifters vary‚ including standard‚ short-throw‚ and aftermarket designs‚ each offering unique benefits for performance‚ reliability‚ or customization to suit driver preferences and vehicle needs.

4.1 Standard Shifters

Standard shifters are the default option for most vehicles‚ offering reliable performance and durability. They are designed to meet OEM specifications‚ ensuring smooth gear transitions and consistent operation. These shifters are typically made from high-quality materials and are built to withstand normal driving conditions. They are a cost-effective choice for drivers who prioritize functionality and simplicity. Standard shifters are widely available from manufacturers like Hurst‚ B&M‚ and Lokar‚ making them an ideal choice for everyday use and long-term reliability.

4.2 Short Throw Shifters

Short throw shifters are designed to reduce the distance between gear shifts‚ offering quicker and more precise control. They are popular among performance enthusiasts and racing applications‚ as they enhance driver responsiveness. These shifters typically feature a shorter lever and optimized linkage‚ allowing for faster gear changes. Short throw shifters are ideal for drivers seeking improved acceleration and agility‚ making them a preferred upgrade for sport-tuned vehicles. They are available from brands like Hurst and B&M‚ catering to both OEM and aftermarket needs.

4.3 Aftermarket and Performance Shifters

Aftermarket and performance shifters are engineered to enhance driving dynamics‚ offering superior precision and responsiveness. These shifters are often lightweight and feature ergonomic designs for better driver comfort. They include adjustable components for customized shifting feel and are popular among racing enthusiasts. Top brands like Hurst and B&M offer high-quality options with short throw capabilities and durable materials. These shifters are ideal for vehicles requiring high-performance gear control and are compatible with various applications‚ including Ford‚ GM‚ and custom builds.

Manufacturers and Their Shifter Assembly Products

Prominent manufacturers like Hurst‚ B&M‚ and Lokar offer high-quality shifter assemblies‚ designed for precision and durability‚ catering to various vehicle applications and performance needs.

5.1 Hurst Shifter Assemblies

Hurst shifter assemblies are renowned for their exceptional quality and precise engineering. Known as America’s Number One Shifter‚ Hurst offers a wide range of models‚ including short throw options. These shifters are designed for both style and performance‚ featuring durable construction and smooth gear transitions. They are compatible with various vehicles‚ including Ford‚ GM‚ and Mopar applications‚ making them a popular choice among automotive enthusiasts and professionals.

5.2 B&M and Lokar Shifter Options

B&M and Lokar offer high-quality shifter solutions known for durability and precision. B&M shifters are celebrated for their short throw action and sleek designs‚ catering to both classic and modern vehicles. Lokar focuses on innovative designs‚ such as their automatic and manual shifters‚ ensuring smooth transitions and enhanced control. Both brands provide versatile options for Ford‚ GM‚ and Mopar applications‚ making them favorites among automotive enthusiasts for their performance and reliability.

5.3 JEGS and Summit Racing Products

JEGS and Summit Racing are leading retailers offering a wide range of manual transmission shifter assemblies and components. JEGS provides shifters from top brands like Hurst and Lokar‚ ensuring compatibility with Ford‚ GM‚ and Mopar vehicles. Summit Racing features an extensive in-stock selection‚ including short throw shifters and rebuild kits‚ with options for popular transmissions. Both companies emphasize quality and performance‚ catering to enthusiasts seeking reliable and precise shifting solutions for their vehicles.

Repair and Replacement of the Shifter Assembly

Repairing or replacing a shifter assembly involves addressing worn components or faulty linkages. Rebuild kits and proper tools ensure precise adjustments‚ maintaining smooth gear shifting functionality and performance.

6.1 Common Issues in Shifter Assemblies

Common issues with manual transmission shifter assemblies include worn-out shift linkage components‚ loose connections‚ and damaged shift boots. These problems can lead to hard shifting‚ misaligned gears‚ and reduced precision. Over time‚ wear and tear on the shift lever and knob can also cause play or vibrations‚ affecting the overall driving experience. Regular maintenance and prompt repairs are essential to prevent these issues from escalating and ensuring optimal performance.

6.2 Rebuild Kits for Manual Transmission Shifters

Rebuild kits for manual transmission shifters are designed to restore shifting performance by replacing worn or damaged components. These kits typically include essential parts like bushings‚ pins‚ and springs. They allow for targeted repairs rather than replacing the entire assembly‚ saving time and money. Popular brands like Dorman and USA Standard Gear offer high-quality rebuild kits compatible with various vehicle makes. These kits are ideal for DIY enthusiasts and mechanics seeking to restore smooth‚ precise shifting to their manual transmissions.

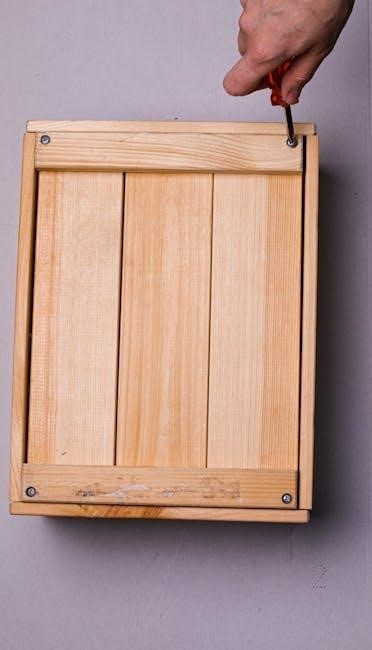

6.3 Step-by-Step Replacement Guide

Replacing a manual transmission shifter assembly involves several systematic steps. Start by disconnecting the battery to prevent any electrical issues. Next‚ remove the shift knob and boot to access the assembly. Then‚ disconnect the shift linkage and cables from the transmission. After that‚ unbolt the shifter assembly from the transmission tunnel. Install the new assembly by reversing these steps‚ ensuring all connections are secure. Finally‚ test the shifter to ensure smooth gear transitions and proper operation. This guide helps ensure a successful replacement process;

Vehicle-Specific Shifter Assembly Applications

Vehicle-specific shifter assemblies are tailored for makes like Ford F150‚ Chevrolet‚ and Mazda‚ ensuring precise compatibility and optimal performance for their respective manual transmissions.

7.1 Ford F150 Manual Transmission Shifter Assembly

The Ford F150 manual transmission shifter assembly is designed for durability and smooth shifting‚ featuring components like the shift lever and knob. It ensures precise gear control‚ enhancing driving efficiency. Ford’s shifter assemblies are often made from high-quality materials‚ providing a long service life. Replacement parts are widely available from manufacturers like JEGS and Summit Racing‚ catering to both OEM and aftermarket needs. Regular maintenance helps prevent wear and tear‚ ensuring optimal performance.

7.2 Chevrolet and GM Vehicle Shifter Assemblies

Chevrolet and GM vehicles utilize high-quality manual transmission shifter assemblies designed for precision and durability. These shifters are engineered to provide smooth gear transitions‚ ensuring optimal performance. GM Genuine Parts offers OEM-grade assemblies‚ while aftermarket options from Hurst and B&M cater to enthusiasts. Compatible with various GM models‚ these shifters are built to withstand heavy use and maintain precise control. Easy to install and maintain‚ they are a reliable choice for both classic and modern Chevrolet applications.

7.3 Ford Focus and Mazda Applications

Ford Focus and Mazda models often feature compact manual transmission shifter assemblies optimized for sporty driving experiences. These shifters are designed for precise control and smooth gear changes‚ enhancing driver engagement. Aftermarket options like short throw shifters are popular for racing and performance tuning. Durable materials ensure longevity‚ while compatibility with various transmission types makes them versatile. Easy to install‚ these assemblies maintain the vehicles’ dynamic handling and responsiveness‚ ideal for both daily driving and enthusiast use.

Troubleshooting Common Shifter Assembly Problems

Troubleshooting common shifter assembly issues involves identifying symptoms like stiff shifting‚ loose components‚ or unusual noises. Regular inspection and timely repairs can prevent major failures and ensure smooth gear transitions. Addressing these problems early maintains optimal vehicle performance.

8.1 Hard Shifting Issues

Hard shifting issues in manual transmissions often stem from worn synchronizers or excessive wear on gear teeth. Additionally‚ low transmission fluid levels or degraded hydraulic systems can cause gears to engage roughly. In some cases‚ misaligned or damaged shift forks may also contribute to the problem. Addressing these issues promptly is crucial to prevent further damage and ensure smooth gear transitions‚ maintaining overall transmission performance and longevity.

8.2 Loose or Worn-Out Shifter Components

Loose or worn-out shifter components can lead to poor gear engagement and shifting difficulty. Common culprits include worn shift forks‚ damaged pivot pins‚ or degraded bushings. Over time‚ these parts may develop play‚ causing misalignment and inconsistent shifting. Replacing or tightening these components with high-quality rebuild kits can restore precision and reliability. Regular inspection and maintenance are crucial to prevent such issues‚ ensuring smooth and responsive gear changes in both everyday driving and high-performance scenarios.

Performance Enhancement Through Shifter Assembly Upgrades

Upgrading the shifter assembly enhances driving performance by improving shift precision‚ reducing throw distance‚ and offering customizable options for a tailored driving experience.

9.1 Upgrading to a Short Throw Shifter

Upgrading to a short throw shifter reduces the distance between gear shifts‚ enhancing acceleration and driver control. This modification is popular among performance enthusiasts‚ as it allows for quicker and smoother transitions between gears. Short throw shifters are particularly beneficial in racing and spirited driving scenarios‚ where precise and rapid shifting is crucial. They often feature durable materials and ergonomic designs‚ ensuring reliability and comfort. This upgrade is a cost-effective way to elevate driving performance without major modifications.

9.2 Custom Shift Knobs and Handles

Custom shift knobs and handles offer personalization and improved grip‚ enhancing the driving experience. Available in various materials like leather‚ wood‚ and aluminum‚ they provide a stylish upgrade. Ergonomic designs reduce fatigue‚ while weighted knobs improve shifting smoothness. Custom options allow drivers to tailor their shifter to preferences‚ combining aesthetics with functionality. This upgrade is a straightforward way to enhance both comfort and performance‚ making it a popular choice for enthusiasts seeking a unique touch in their vehicles.

Modern Innovations in Manual Transmission Shifter Design

Modern innovations include automated manual transmissions (AMT) and EV-specific shifter solutions‚ offering electronic automation and sleek‚ compact designs for enhanced efficiency and driver convenience.

10.1 Automated Manual Transmissions (AMT)

Automated manual transmissions (AMT) integrate electronic automation‚ eliminating the need for manual clutch operation while retaining the efficiency of a manual transmission. These systems use sensors and actuators to automatically engage and disengage the clutch‚ simplifying gear shifts and improving fuel efficiency. AMTs are particularly popular in urban driving conditions‚ offering a smooth and stress-free experience. They combine the benefits of manual and automatic transmissions‚ making them a versatile choice for modern vehicles.

10.2 Electric Vehicle (EV) Shifter Assembly Solutions

Electric vehicles (EVs) are redefining traditional shifting with innovative shifter assemblies that combine modern aesthetics with functionality. While EVs typically don’t require multi-speed transmissions‚ some models incorporate manual-like shifters for familiarity and driver engagement. These shifters often feature minimalist designs‚ integrating digital controls and paddle-shift systems. Ford’s patented EV shifter assembly‚ for instance‚ mimics manual transmission patterns‚ offering a unique driving experience. EV shifters also focus on sustainability‚ using lightweight materials and energy-efficient designs to enhance overall vehicle performance while maintaining a classic shifting feel.

DIY Rebuilding of the Shifter Assembly

Rebuilding a manual transmission shifter assembly requires specialized tools and genuine parts‚ such as Dorman kits‚ to restore smooth shifting and optimal performance efficiently.

11.1 Tools and Parts Required for Rebuilding

Rebuilding a manual transmission shifter assembly requires specific tools like torque wrenches‚ screwdrivers‚ and punches. Essential parts include shift rebuild kits (e.g.‚ Dorman 917-551)‚ shift knobs‚ boots‚ and gear selector components. Manufacturers like Hurst and B&M offer high-quality replacement parts. Ensure all components are compatible with your vehicle’s make and model for optimal performance. Sourcing genuine parts from retailers like Summit Racing or JEGS ensures reliability and proper fitment during the rebuild process.

11.2 Disassembly and Reassembly Techniques

Disassembling the shifter assembly involves removing the shift knob‚ boot‚ and linkage components. Use specialized tools like torque wrenches and punches to avoid damaging parts. Reassembly requires precise alignment of gears and linkages‚ ensuring smooth operation. Refer to factory manuals for torque specifications and proper reinstallation sequences. Apply threadlocker to fasteners for stability. Test shifting functionality post-reassembly to confirm proper engagement and eliminate play.

Advantages of a High-Quality Shifter Assembly

A high-quality shifter assembly enhances driving precision‚ ensures smooth gear transitions‚ and improves overall vehicle control‚ offering reliability and durability for an elevated driving experience significantly.

12.1 Improved Gear Shifting Precision

A high-quality shifter assembly ensures precise gear engagement‚ reducing wear on transmission components. Its refined mechanical linkage and detent springs provide clear‚ defined shifts‚ enhancing driver control and satisfaction. The solid connection between the shift lever and gearbox minimizes play‚ allowing for accurate gear transitions. This precision not only improves performance but also reduces the risk of misshifts‚ making driving smoother and more enjoyable. It’s a critical upgrade for both everyday commuting and high-performance applications.

12.2 Enhanced Driving Experience

A high-quality shifter assembly elevates the driving experience by providing smooth‚ precise gear transitions. Drivers enjoy better control and connection to the vehicle‚ making every shift feel intentional and satisfying. Reduced mechanical play and consistent engagement enhance responsiveness‚ while the solid linkage minimizes unwanted movement. This results in a more engaging and enjoyable drive‚ whether navigating city streets or pushing limits on performance roads‚ ensuring a rewarding experience for both casual and enthusiast drivers alike.

Challenges in Shifter Assembly Maintenance

Wear and tear on components‚ such as the shift lever and linkage‚ can lead to mechanical failure. Additionally‚ compatibility issues with aftermarket parts may arise‚ requiring precise adjustments.

13.1 Wear and Tear of Components

Over time‚ the manual transmission shifter assembly components‚ such as the shift lever‚ linkage‚ and bushings‚ experience wear and tear. This can lead to loose connections‚ difficulty in shifting gears‚ and reduced precision. Factors contributing to wear include frequent use‚ high-stress driving conditions‚ and lack of lubrication. Replacing or rebuilding these components is essential to maintain optimal shifting performance and prevent complete system failure.

13.2 Compatibility Issues with Aftermarket Parts

Aftermarket parts for manual transmission shifters may not always be compatible with the original equipment‚ leading to potential installation and performance issues. Differences in design‚ material quality‚ or manufacturing standards can cause misalignment or improper fitment. Ensuring that aftermarket components are specifically designed for the vehicle’s make and model is crucial to maintain functionality and avoid mechanical problems. Compatibility checks are essential before purchasing or installing any aftermarket shifter assembly parts.

Future Trends in Manual Transmission Shifter Assembly

Future trends include integration with advanced automotive technologies and sustainable material innovations‚ enhancing performance‚ efficiency‚ and environmental friendliness while maintaining the classic appeal of manual shifting systems.

14.1 Integration with Advanced Automotive Technologies

Manual transmission shifter assemblies are being integrated with advanced automotive technologies‚ such as automated systems and electric vehicle (EV) platforms‚ to enhance performance and driver experience. Ford’s patented EV shifter replicates manual shifting patterns‚ while GM incorporates cutting-edge materials and software for seamless operation. These innovations ensure that manual transmissions remain relevant in modern vehicles‚ offering a blend of tradition and futuristic design.

14.2 Sustainability and Material Innovations

Modern manual transmission shifter assemblies are embracing sustainability through eco-friendly materials and innovative manufacturing. Companies like GM and Ford are adopting lightweight‚ corrosion-resistant alloys and recycled components‚ reducing environmental impact. Advanced 3D printing and CNC machining techniques enable precise production with minimal waste. These innovations ensure durability while aligning with global sustainability goals‚ making manual transmissions more environmentally responsible without sacrificing performance or driver satisfaction.

The manual transmission shifter assembly remains vital for precise gear control and driving experience‚ with advancements in design‚ sustainability‚ and performance ensuring its continued relevance in modern vehicles.

15.1 Summary of Key Points

The manual transmission shifter assembly is a critical component for precise gear control and driving performance. It consists of essential parts like the shift lever‚ knob‚ and linkage‚ ensuring smooth operation. Top manufacturers such as Hurst‚ B&M‚ and JEGS offer high-quality options tailored to various vehicles‚ including Ford‚ GM‚ and Mazda models. Common issues like hard shifting or worn components can be addressed with repair kits or upgrades. Regular maintenance and compatibility checks are vital for optimal functionality and longevity‚ while upgrades like short-throw shifters enhance performance and driver satisfaction.

15.2 Final Thoughts on Manual Transmission Shifter Assembly

The manual transmission shifter assembly remains a vital component for drivers seeking precision and control. With advancements in design and materials‚ modern shifters offer enhanced performance and durability. Whether for daily driving or racing‚ high-quality shifters from reputable manufacturers ensure reliability. As automotive technology evolves‚ the shifter assembly continues to adapt‚ blending tradition with innovation to meet the demands of both classic and future vehicles‚ making it a cornerstone of driving excellence.